Regeneration of press axles

In this article, we will tell you about one of the most demanding realizations – the remanufacturing of two axes of the BA1642 industrial packet press with a pressure of 16,000 kN, carried out by our specialists using Sir Meccanica and Supercombinata equipment.

The work was carried out in 2019 on an industrial site, outdoors, in difficult weather conditions – the temperature was not very cold, but ranged from +2 to +5°C, with strong winds and rainfall.

Despite this, the renovation was carried out exactly on time, and its quality was assessed at the highest level, allowing the customer to start the press on time and complete the export contract without any losses.

Scope of the task

Two axes of the huge BA1642 press had to be reconditioned – both in the pressure plate and in the opposite part of the frame (stanin).

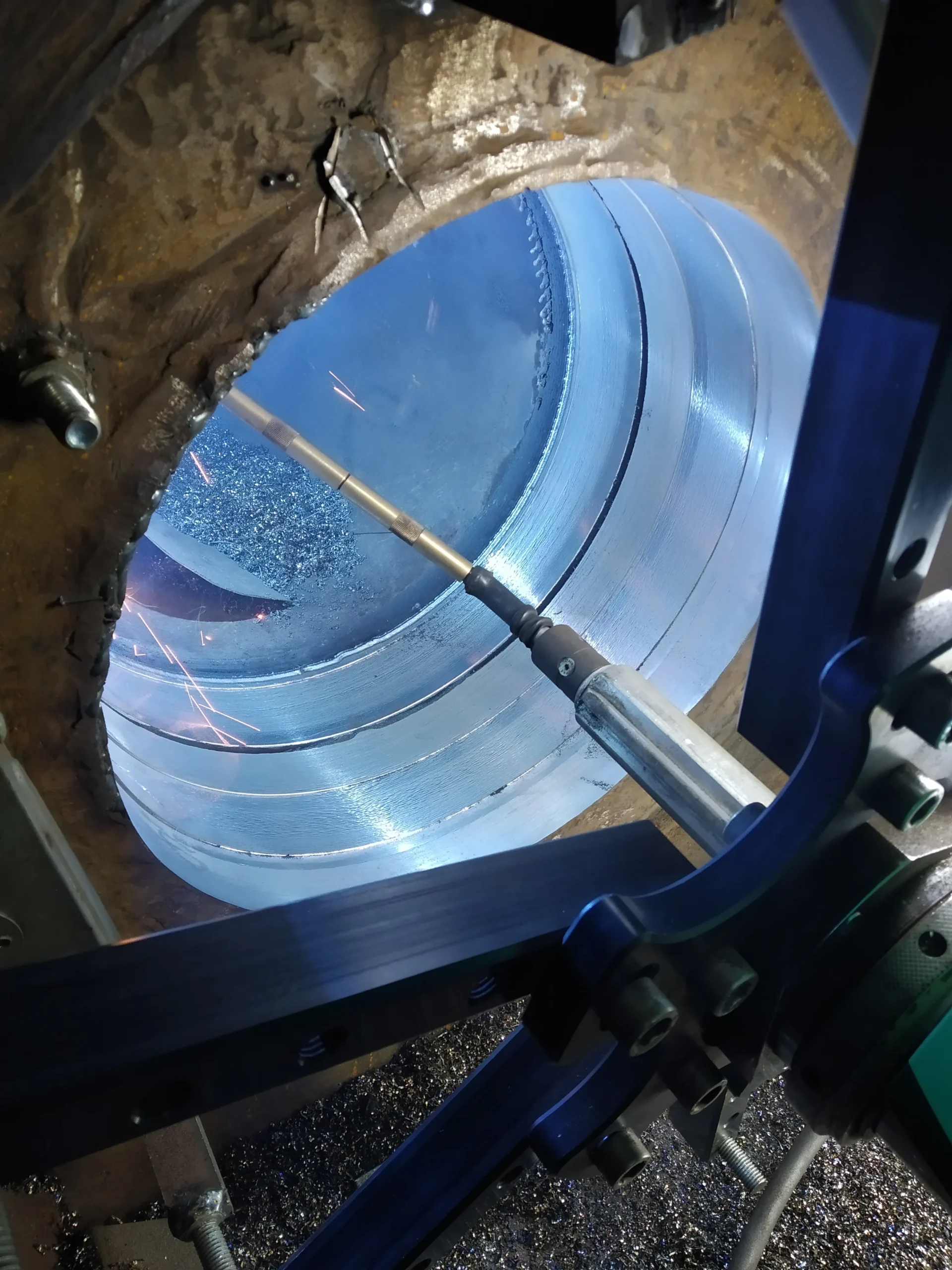

The holes to be repaired had a diameter of about 440 mm and a depth of 400 mm each.

After boring and leveling the surface, it was necessary to surfacing the holes and then machining to the original size for the installation of bronze bushings.

The work was a lot, and the pressure from the customer increased every day.

Equipment used

The implementation involved three specialists who used two Italian boring machines from different manufacturers:

- Supercombinata SC60 – with a 60 mm diameter spindle;

- Sir Meccanica WS2 Standard – with a 40 mm spindle (used for surfacing and roughing).

These were the most popular and reliable hole reconditioning machines available on the market at the time – but they weren’t among the cheapest either.

By combining these machines, it was possible to achieve high alignment accuracy and maintain the required geometric parameters.

Although it wasn’t without problems – as we’ll tell you further on.

In 2023, we launched our own production line under the Borweld brand, creating state-of-the-art mobile boring machines for repairing holes in construction, agricultural, forestry and industrial machinery.

🔗 See more: Borweld Smart 40-1.0 mobile boring machine

or visit the Store – Borweld.

Difficulties and specifics of the project

1. Geometric accuracy

The most difficult part was aligning the axis of the pressure plate perfectly perpendicular to the axis of rotation of the opposing part.

A lot of time was spent on this step, using various tools and jigs to align the equipment.

Although the structure was rectangular, when assembled it had to enter the working space perfectly with a clearance of about 10 mm per side.

Any deviation could have led to skewing or damage to the press components.

And the failure of such a powerful piece of equipment is not only a costly overhaul, but also a serious loss due to downtime and loss of customer confidence – it would be a blow to the reputation for the contractor.

2. Working conditions

The work was carried out outdoors, so it was necessary to build a temporary canopy that at least partially protected from wind and rain.

The temperature and humidity significantly hampered the process of surfacing large holes.

During the welding process, the regulators on the gas cylinders froze, and the equipment itself required regular cooling breaks.

Several cylinders of welding compound were consumed in a single day, and a total of about 8 × 15 kg of ESAB Ø1.0 mm wire.

You can imagine the enormous amount of labor required to consume such a quantity of material.

Equipment failure and repair

Conditions were difficult, and the machines were working at full load.

At some point, as it happens, there was a failure of one of the boring machines – the brush module of the motor burned out.

It would have taken an eternity to complete the entire project with only a smaller machine with a 40 mm spindle, so the situation was serious.

Fortunately, we were able to quickly contact the manufacturer and order replacement parts on an urgent basis.

Delivery from Italy took only 5 days, after which the machine was repaired in a few hours and immediately returned to work.

The team continued to implement in two shifts to meet the agreed deadline.

Boring and surfacing process

The most difficult part was behind us.

After preparing the holes, we performed surface welding and then precision boring to the nominal dimension.

All parameters were maintained according to the technical documentation.

The customer, however, required that it perform Additional fit tolerance – the holes were to be about 0.2 mm smaller .

To be honest, we had doubts about installing the bushings correctly later on, but we decided to trust the calculations and experience.

Bushing assembly with liquid nitrogen

To assemble the two bronze bushings, four Dewar tanks and 100 kg of liquid nitrogen were purchased – a cost that seemed significant at the time.

As mentioned earlier, the fit was to be very tight, so the bushings had to be cooled to extremely low temperatures.

Under the influence of liquid nitrogen, the metal shrank, and the bushings entered the holes very lightly, despite the large allowance.

The whole operation took about 15 minutes – during this time the entire supply of nitrogen was used up, and the bushings were perfectly seated.

Effects of work

- The 440mm diameter holes have been fully restored.

- The fits were made with micron accuracy.

- The press was launched without any downtime or loss of contract.

- The team has gained extensive experience in repairing and machining large holes in difficult terrain.

⏱ Lead time

The total time to complete the project was three weeks, including waiting for spare parts and repairing the boring machine.

The work was carried out six days a week, 8-10 hours a day.

The project involved three specialists who worked two shifts after an equipment breakdown to meet the deadline.

Despite all the difficulties, the project was completed on time and with the highest quality.

Conclusions and recommendations

For the regeneration of holes with large diameters, you need a boring bar with a diameter of at least 50 mm – preferably 60 mm.

Vendors who claim that a machine with a 40 mm spindle can effectively process holes with a diameter of 400 mm are mistaken.

Such an operation can be performed for months – or completed in a few days with the right equipment.

Nothing is impossible – you just have to not be afraid of big and difficult projects.

It is in such assignments that you gain experience and real money.

See also

- VIC1000 press reconditioning – boring 34 holes over a length of 8 m

- Hole surfacing – a technical guide

- Set of external micrometers – measuring tools

✅ The realization of the BA1642 press repair is an example of how experience, precision and reliable equipment make it possible to solve tasks that seem seemingly impossible.

If you need remanufacturing of axles, bores or bushings in industrial machines –

📞 contact us through the contact form.