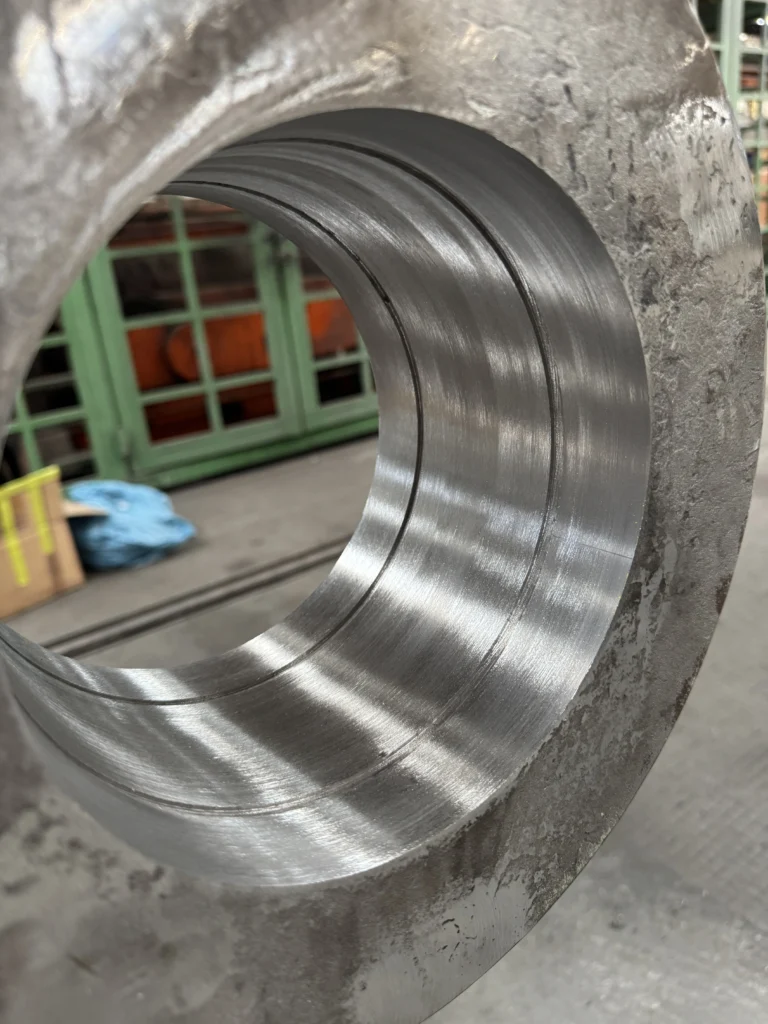

We have performed in Swidnica a comprehensive boring of holes for port crane components manufactured on the local production hall. 6 details were machined, diameters 50-180 mm, and we also made grooves for circlip rings – all at the manufacturer’s site. From the customer’s information, the finished assemblies will go for export. The project showed that in a large manufacturing plant not only the speed of machining matters, but also logistics, coordination of assemblies and quick technological arrangements.

Hole boring. Background and objectives

- Location: manufacturing plant in Świdnica (Poland)

- Purpose of details: port crane components for export project

- Schedule: Mon-Fri (leave Krakow at 7:00 a.m., work until 5:00 p.m.)

- Scope: boring of 6 workpieces + grooves for circlips

- The premise: maximize non-surfacing work where possible to reduce downtime. In practice, the pace was also determined by the readiness of details and agreements between departments.

Key challenges and our solutions

- One of the parts was not ready on the first day → we rescheduled the order and ran parallel work on 2-3 BORWELD SMART.

- Cut marks on one of the holes → local surfacing necessary (after technology approval).

- Very little assembly space when machining tower nodes → we used a short BORWELD SMART drive unit (~320 mm, internal feed) that fits where large machines don’t stand a chance.

- Long flights and long wheelbases → combined shafts (2.2 m + 1 m on Morse cone), centering cones and four supports for rigidity.

- Grooves for circlips on all holes → our special groove head + coolant for blade life and edge quality.

Course of work (day by day summary)

Day 1: arrived, agreed on a plan with the technologist, started around noon. We completed the first detail; an edge defect was detected on the second – the decision was made to surfacing.

Day 2: completing the axle after surfacing; in parallel, we started a deep hole detail, but after the first pass, it became clear that there was not enough material in places – local surfacing was set for the morning of Day 3.

Day 3: after surfacing, we quickly finished the detail; the second operator conducted large diameter machining – due to the long vias, we managed to complete 1 of the 2 holes.

Day 4: machining tower mounting holes (3 holes on one axis, limited space). The short unit worked perfectly; centering through the transport holes and cones. Work without surprises.

Day 5: we set off with four holes of the next detail (after the morning preparation corrections). Three required manual surfacing – we made them on site. With two machines working in parallel, we finished all the holes and grooves by 5 pm. Departure to Krakow.

Effect

- 6 details machined in 5 working days.

- Holes and grooves made according to drawings and tolerances, ready for further assembly and shipping.

- Downtime minimized: where surfacing was not necessary – we worked immediately; where it was needed – we completed it quickly on site.

Quality control of hole цytyting and documentation

We close each order with a formal quality inspection. After machining, we measure diameters, concentricity and runout of shafts using dial gauges (0.01 mm) and diameter/calibers. For grooves, we verify width, depth and transition radii; we also check roughness upon request. We take “before/after” photos, mark the workpieces, and record the results in a measurement certificate with reference to drawings and tolerances. If test fitting of pins or bushings is required, we arrange it on site. This procedure shortens acceptance, facilitates quality tracking in the supply chain, and secures assembly after shipment (even for export projects). We provide documentation in PDF and, on request, in hard copy.

Why BORWELD SMART works well in manufacturing

- The compact unit (internal feed) works where large machines lack space.

- Modular shafts and supports provide rigidity for long passages.

- Field/halal format: quick changeovers, ability to work from aggregate.

- Special heads (e.g., for grooves) = full cycle on one basing.

Do you need similar processing or want to run it at your place?

- Have the boring done at the production/site: Boring of holes

- Buy your own BORWELD SMART boring machine (sales, implementation, training): Mobile boring machine – powerful, lightweight and compact

Write to us – we will prepare a cost estimate and schedule for your project; you can also get in touch via our social media (Facebook, LinkedIn, Instagram) or WhatsApp.