Does your machinery need bore reconditioning? Boring and bushings are processes that restore the efficiency of worn connections in construction and industrial machinery. With our services, your machines can operate precisely and trouble-free for many years to come.

What is boring and bushing?

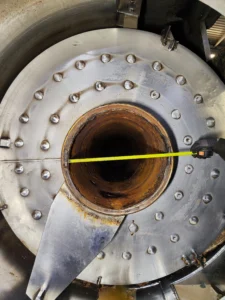

Hole boring is the process of machining worn holes to restore them to their proper shape and size. The holes are reamed to a slightly larger size to get rid of deformities such as ellipses.

Hole bushings are the next stage of remanufacturing, in which one or more layers of metal are surfaced, and then the holes are re-bored to original dimensions or to a size that matches the bushings and pins.

Why Take Advantage of Boring and Bushing?

- Saving Time and Money: We carry out these processes directly on site, eliminating the need to transport machinery.

- Life Extension: Hole regeneration means working components can last longer without failure.

- Precision: With our state-of-the-art boring machines, we ensure the highest quality machining.

How Do We Work?

- Diagnosis: By evaluating the condition of the holes, we select the appropriate method of regeneration.

- Boring Holes: Ream holes to a larger size to remove deformations.

- Welding and Re-boring: Weld the metal and bore the hole to final size for bushings or pins.

Our Advantages

- Mobility: we perform the work directly on site, which minimizes downtime.

- Modern Equipment: We work on professional boring and boring machines.

- Many Years of Experience: We have 15 years of experience in the industry.

- Flexible Approach: We tailor our services to the customer’s needs.

Contact Us

If your machines require boring or bushings, contact us! We work quickly, precisely and professionally.

Call now or visit our website to learn more!

[trustindex no-registration=google]