How to align the boring bar with cones and centering kit

One of the key steps when boring holes in construction and industrial machinery is boring bar alignment.

The accuracy of the repair, the life of the bushing and the overall geometry of the component depend on the correct execution of this operation. Even a slight misalignment of the axis can lead to skew, uneven operation and accelerated wear of the connections.

In this article, we will discuss in detail how to properly align the spindle with cones and a centering set, what tools are needed and what to pay attention to while working.

Preparation of the component for assembly

Before beginning assembly, the surface of the component must be properly prepared.

Any layer of dirt, rust, weld residue or paint will affect the accuracy of alignment. The surfaces to which the centering set plates will be welded should be thoroughly cleaned and leveled. This will ensure stable metal contact and avoid skewing during welding.

If you want to know which reconditioning method to choose – bush boring or surfacing, read the article Bushing boring or boring with surfacing.

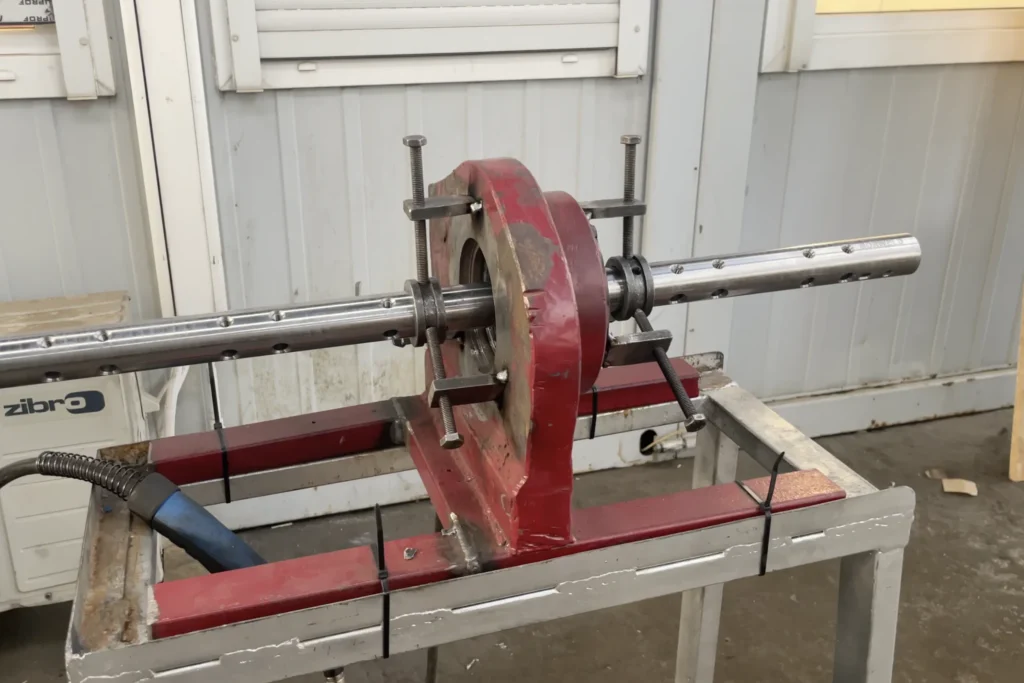

1. Boring bar alignment with cones

(not included in the standard kit)

If the hole has minimal wear (up to 2 mm) and does not have a clear oval, tapers can be used. This is one of the easiest and fastest methods of setting the spindle.

The process is as follows:

- On the boring bar we put two cones of the appropriate diameter.

- Use the cones to attach the boring bar to the part.

- Next, measure the distance from the boring bar to adjacent axes, edges or structural components to make sure everything is aligned symmetrically.

For additional inspection, you can use a laser level to visually check the concentricity. If the plane of the workpiece and the axis of the boring bar coincide, you can proceed to the next step – installation of supports.

You can read more about line boring technology itself in the article

Mobile boring – the key to efficient repair of heavy machinery.

However, the use of cones is not always possible. If the hole is heavily bumped or elliptical in shape, it will be difficult to align the spindle accurately. In such situations, a centering set is used – a universal solution, suitable for any degree of wear.

2. Boring bar alignment with – precise alignment with any wear and tear

The centering kit consists of:

- two rings,

- six screws,

- and six plates that are welded to the component.

Before installation, make sure that the tiles have been cleaned of paint and rust, and that the surface underneath is even. Even a slight unevenness or a drop of old grout can cause an alignment error.

First assemble the kit, determine the center of the hole and spot weld the plates. This makes it easy to remove them if necessary without damaging the component.

Screw placement and kit preparation

Recommended screw setting:

- One screw at the bottom (6 o’clock position),

- Two screws at the top (10 o’clock and 14 o’clock positions).

This arrangement facilitates vertical and horizontal adjustment. After welding the plates, remove the screws and rotate the ring – the screws must not block the threads.

In the video, the screws were set in reverse due to the nature of the design.

Checking concentricity – tools and method

At this stage, accurate centering is performed.

Two tools can be used for this operation:

- measuring stick (stichmas),

- Or a lathe knife (if you don’t have a stick on hand).

The stichmas should be placed in the bar and locked with the mounting screw.

While turning the boring bar, we measure the smallest distance from the boring ber axis to the edge of the hole. We divide the obtained dimension in half, and then gently tighten the screws in the rings until the clearance around the entire circumference becomes equal.

If the distance between the pin and the edge of the hole is the same at several points, the boring bar has been set correctly. Then repeat the procedure on the other side, and check the first one again to exclude offsets after adjustment.

The principle is simple:

“Seven times measure, once cut.”

Accurate alignment takes time, but it is the foundation of a solid and lasting repair.

Completion of assembly and transition to boring

Once alignment is checked, the supports can be welded, the centering set can be removed and the machine can be mounted.

Borweld’s work uses a compact and precise system Borweld Smart hole boring machine – precision, mobility and European quality, which allows you to perform hole reconditioning without disassembling the parts.

You can read more about why we built our own machine in the article

Mobile boring machine from practitioners – why we built our own machine.

Summary

Using cones or a centering set are two proven ways to align the spindle coaxially when boring holes.

If the hole is only slightly worn – cones allow you to quickly and accurately align the axis.

If the hole is more worn or distorted – a centering set guarantees precise alignment even under difficult conditions.

The method works particularly well for repairing construction, road, port and agricultural machinery. It makes it possible to work with any degree of wear, ensuring the accuracy, stability and safety of the process.

For more precise centering, we also use a total station, often used in the production of crane components and large diameters.

In combination with modern Borweld mobile machines, we achieve maximum efficiency in repairs – quickly, reliably and with full precision.

📖 Also recommended: