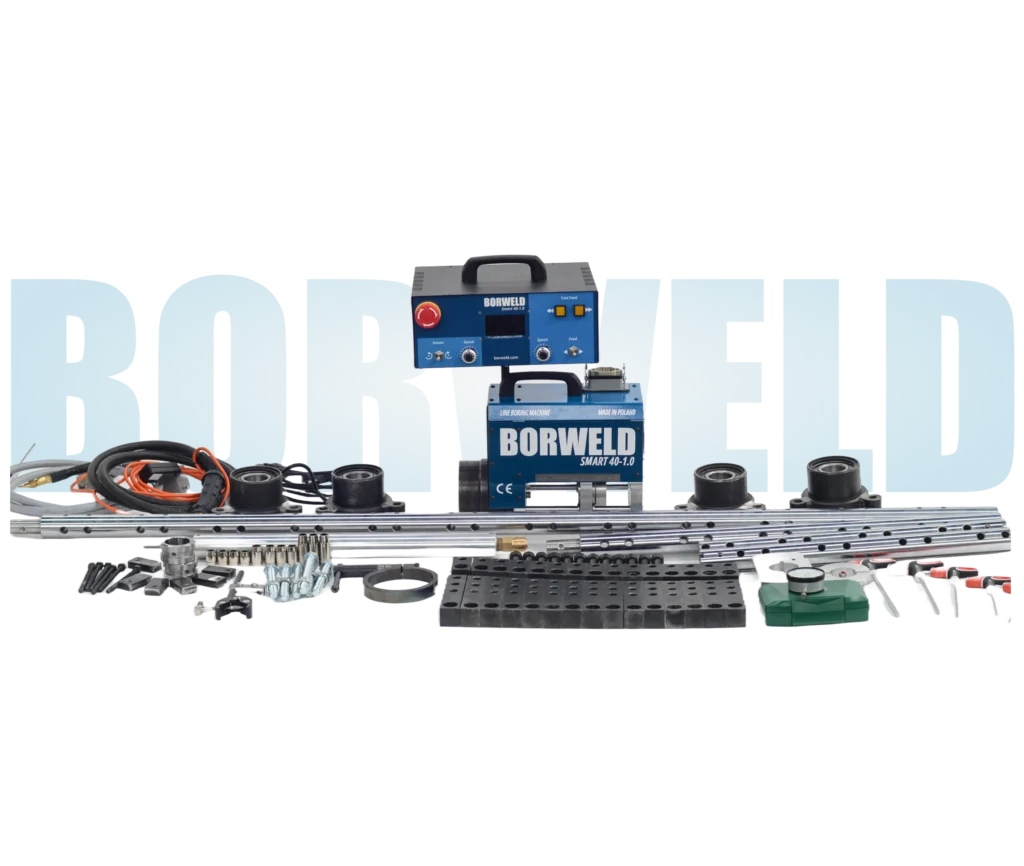

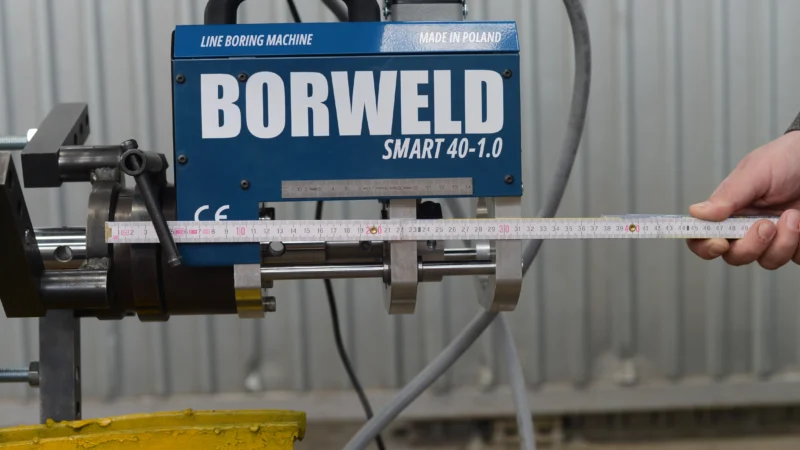

Borweld Smart 40-1.0 mobile boring machine

Buy a tool that makes money from day one

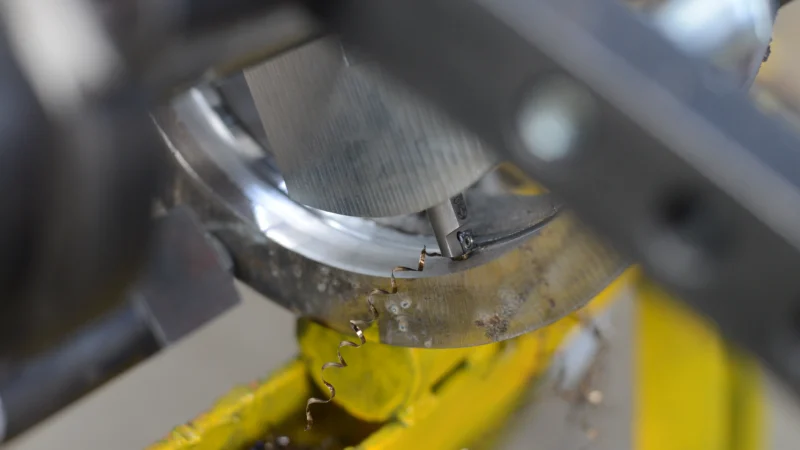

Smart 40-1.0 fully covers all needs for reconditioning and repairing holes in construction, agricultural and forestry machinery. Indispensable in tight and hard-to-reach places

📦 Weight: 13.7 kg

🎯 Spreading range: 22-250 mm

🔥 Welding: 30-250 mm

Designed to work

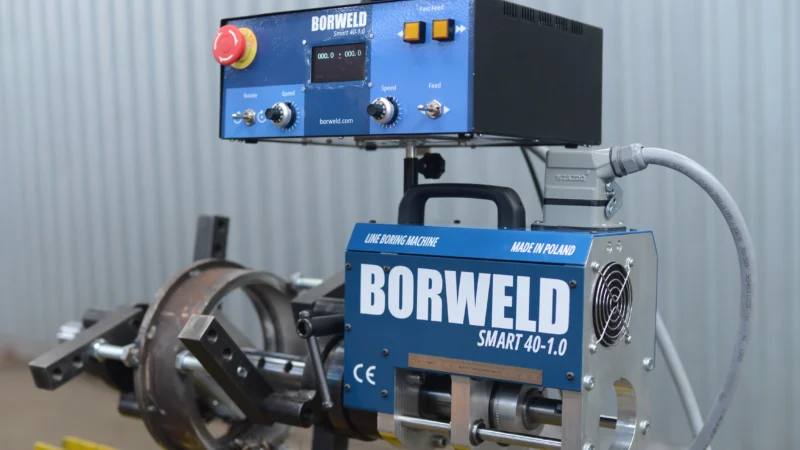

Thanks to its light weight, size and modern control, performing repairs on construction, forestry and agricultural machinery has become faster and easier. In addition, the operator of our boring machine no longer has to lift heavy machines that usually weigh 30-40 kilograms and cannot be used in tight and hard-to-reach places.

- The boring machine fits perfectly:

- For professionals operating in the bronze,

- for beginners,

- for exit repair,

- For repairs in a stationary workshop,

- When working in hot and cold weather

- indispensable in tight and hard-to-reach places

Why Smart 40-1.0?

We have been repairing boreholes for many years. We are not just salesmen – we are practitioners with many years of experience.

⚙️ Versatility

Rollout: 22-250 mm.

Hardfacing: 30-250 mm.

One machine – many possibilities. Covers all your needs for reconditioning and repairing holes in construction, agricultural and forestry machinery

🪶 Only 13.7 kg

We do not know of a smaller and lighter machine on the market. Easy to transport and assemble.

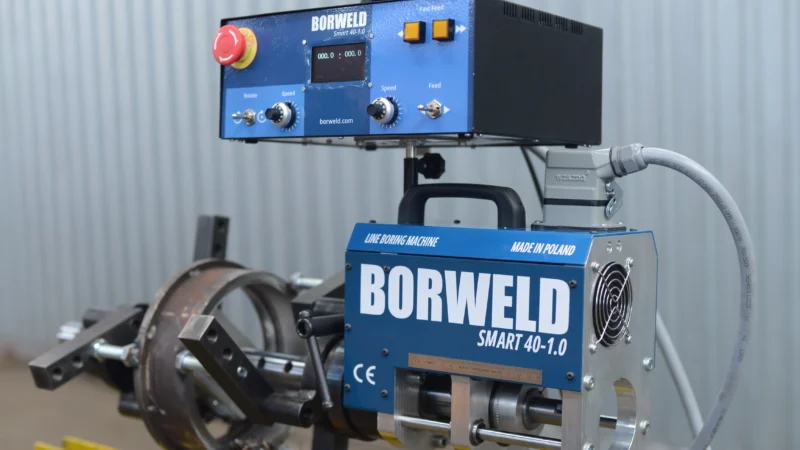

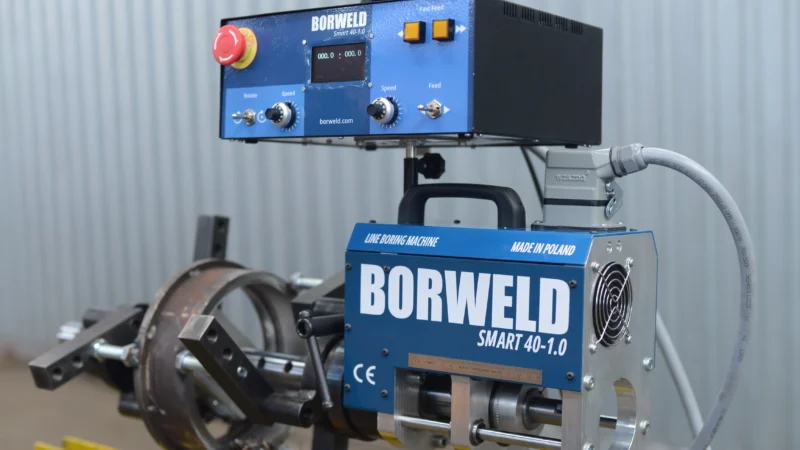

📱 Smart Electronics

A modern digital panel shows all key parameters: motor load, direction, speed.

🎓 Training

We provide training at our workshop or at the customer’s site. We will show and train the repair technology that we have been perfecting for years

🧠 Easy and intuitive operation

It works without complications – it is equally easy for people with any background

🇪🇺 Components from the EU

90% of parts manufactured in Poland. Durability and reliability.

Various configurations

We have been repairing boreholes for many years. We are not just salesmen – we are practitioners with many years of experience.

Main features

- Boring range (standard): 42 - 250 mm

- Boring range (optional): 22 - 250 mm

- Weld range: 30 - 250 mm

- Machine weight: 13.7 kg

- Weight of the set: 95 kg

- Country of origin: Poland (EU)

Smart 40-1.0 comprehensively covers all work related to regeneration and repair of holes in construction, agricultural and forestry equipment. Indispensable in narrow and hard-to-reach places.

Standard equipment

Boring bars:

- Ø40 mm, length 700 mm – 1 piece. (Compact)

- Ø40 mm, length 500 mm – 2 pcs. (Compact)

- Ø40 mm, length 1000 mm – 1 piece. (Pro)

- Ø40 mm, length 1600 mm – 1 pc. (Standard, Pro)

Assembly and mounting:

- 4 mounts (2 bearings)

- Mounting extensions (paws) 60 mm – 12 pcs.

- Mounting extensions (paws) 150mm – 12 pcs.

- Centering rings – 2 pcs.

- Pins M8×150 mm – 6 pcs.

- Centering matrices 50×26×12mm – 6 pcs.

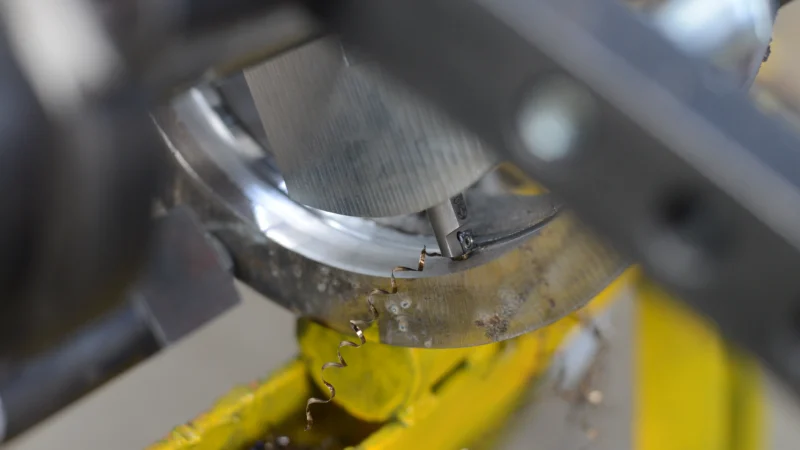

Boring tools:

- Holder for removable inserts (4 types)

- CCMT06 replacement plates – 10 pcs.

- Diameter gauge – 1 pc.

Control system:

- Remote control

- Connection cable with connectors

Resurfacing kit:

- Telescopic welding shaft: Ø40 mm, length 500+300 mm (Compact)

- Telescopic welding shaft: Ø40 mm, length 1000+700 mm (Standard, Pro)

- Connection cable for welding machine: 3 m

- Extension cords up to 170 mm and 250 mm

- Short and long nozzles

- Current tips

Additional accessories:

- Allen wrench and socket wrench sets

- Dial sensor

- Dial sensor holder

Customer reviews

Precision bore reconditioning, modern technology and fast execution of repairs.

Chłopaki znają się na tym co robią i mają normalne ceny

“I recommend tom company is conscientious and professional in what it does.”

Vladimir Kluska

Driver

“I recommend! The guys know what they are doing and have normal prices.”

Szymon Leszczynski

Driver

“Super boring machine. I assemble quickly and can work alone. It was a hit.”

Peter

Entrepreneur

“Short deadlines professional work very friendly employees and Boss overall very great plus”.

Gregory

Entrepreneur

“Full professionalism. Everything as agreed performed on time. I recommend! “

Tomasz Swiecicki

Entrepreneur

Video review

Video gallery

Precision bore reconditioning, modern technology and fast execution of repairs.

Gallery

Frequently asked questions

How much does it cost?

We strive to be flexible and adapt to the needs of each customer.

Therefore, we have prepared several standard configurations, which we believe are the most effective for various applications.

We also offer the possibility to configure your own kit, tailored to your individual needs and budget. The price of each kit is available on our website after registration.

What guarantee do you give?

We offer a standard warranty: 1 year and 2 years for customers from the European Union.

In addition, we offer an extended warranty option with a replacement machine.

In this case, in addition to the standard warranty obligations, we also guarantee the shipment of a replacement machine for the duration of the warranty repair, within 2 working days.

How does your equipment differ from Italian machines?

Our machines stand out from not only Italian, but all other solutions:

lower weight, compact dimensions, and comfortable and ergonomic work.

We are the only manufacturer that has done work on this type of machine ourselves over the years. This has resulted in a solution that makes the operator’s work easier, faster and more comfortable.

Do you offer training?

In addition to the production of machines, we also conduct training courses, where we teach anyone willing to learn the specifics of working in this industry.

In the course of training, we share techniques and experience that we have perfected over the years.

Do you provide support for questions or problems?

Any of our customers can contact us at any time for help or consultation in carrying out more difficult work.

We are happy to answer questions and provide practical advice. Besides, we are always ready to carry out joint works together with our clients.

Where can I see the machine?

You can see our machines on our social media or on site – at our plant in Krakow.

Do you have any questions?

Consultations are free of charge. We will help you solve your problem and understand the situation